The Ultimate Guide to Fixing Your Bambu Lab Printer

Share

Troubleshooting Your Bambu Lab Printer's AMS System

Are you experiencing challenges with your Bambu Lab 3D printer, particularly with the Automatic Multicolor System (AMS)? You're not alone. Many users, including myself, have encountered issues with the color switching mechanism in models like the X1 Carbon and P1S. This problem can significantly increase print times and affect your deadlines, especially if you're printing for clients.

The Core Issue: Filament Unloading Problems

The primary problem arises during the filament switching process. The AMS is designed to unload the current filament and load the next color. However, complications can occur if the PTFE tubes within the system are misaligned or bent, creating friction. This friction hampers the smooth unloading of the filament, leading to a stalled printer. This is the error code that comes up on the screen:

You then have to manually intervene, using a specially designed 3D printed tool to extract the filament from the buffer spring box, as shown in the image below.

Such interruptions not only delay your print but also jeopardize timely order completions.

My Personal Struggle and Solution

Facing this issue across all three of my Bambu printers was a source of significant stress. After scouring the internet for solutions, I came across a variety of suggestions, but one, in particular, proved to be the game-changer: the AMS buffer injector guide. I discovered this ingenious model on makerworld.

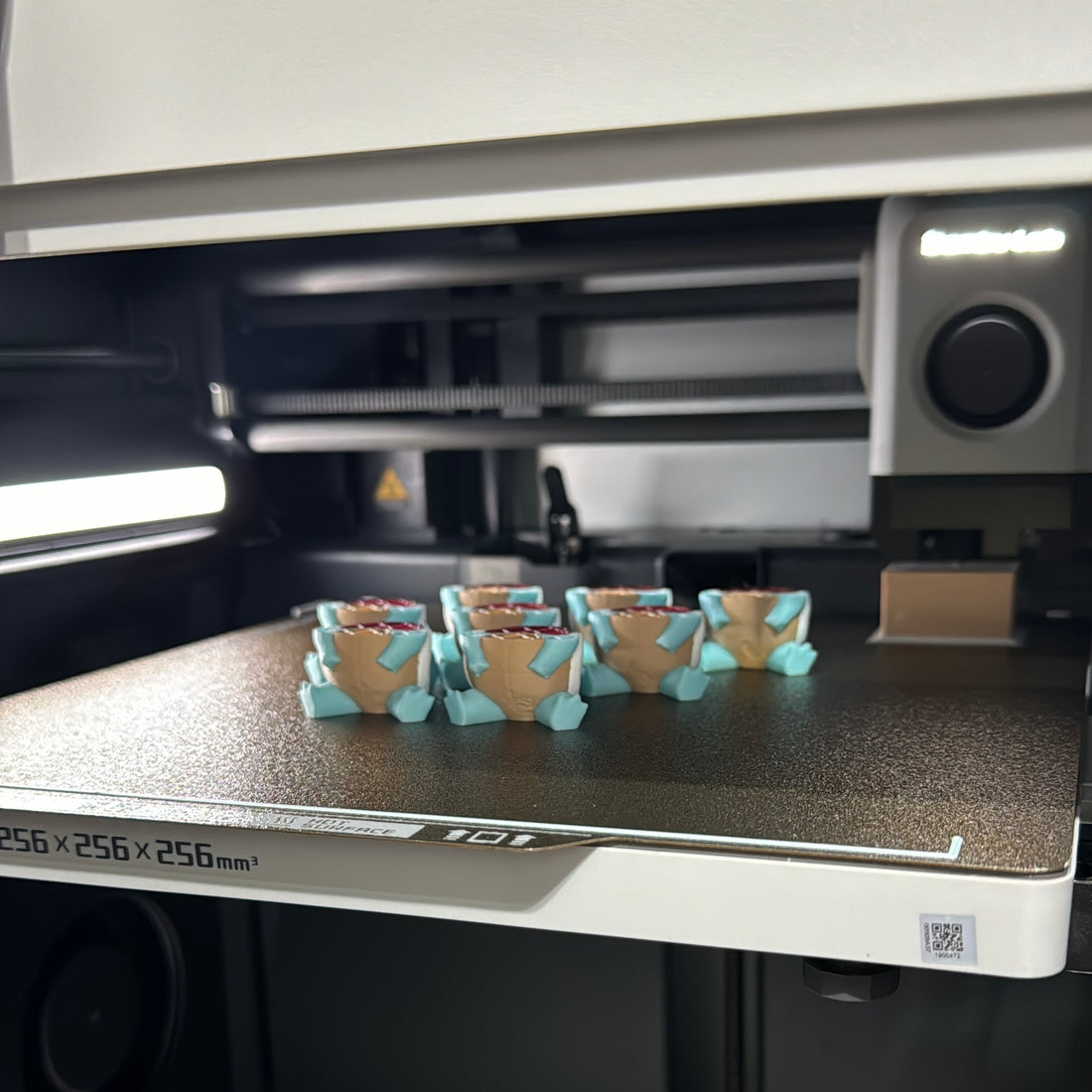

This model, which I printed using durable PLA+ from Numakers, was straightforward to produce and install. Once fitted onto the P1S and X1 Carbon, as illustrated in the following image, it effectively resolved the filament unloading issue.

The buffer injector guide aligns and guides the filament, reducing friction and preventing the previously encountered stalls.

A Solution Worth Trying

For those struggling with similar issues in your Bambu Lab printers, I highly recommend trying out the AMS buffer injector guide. It's a relatively simple and cost-effective fix that could potentially save you hours of frustration and keep your printing projects on schedule.

Link to the file: https://makerworld.com/en/models/97066#profileId-103621

We all know how critical reliability is in 3D printing, especially when client deadlines are at stake. With this solution, I've seen a complete turnaround in the performance of my AMS system. Hopefully, it brings the same relief to your 3D printing endeavors.

Heads up! Some of the links in this post are affiliate links, which means I may earn a small commission if you purchase something through them. I only recommend products and services that I truly believe in and have used myself. Thank you for supporting my work!